Pneumatic and Hand Operated Bottom Blowdown Valve – 33602

Sayfa İçeriği

TogglePneumatic and Hand Operated Bottom Blowdown Valve – 33602

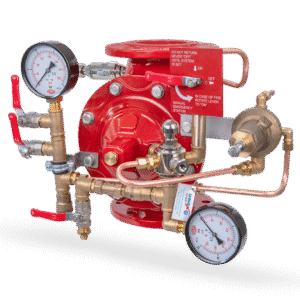

The Pneumatic and Manual Bottom Blowdown Valve – 33602 ensures safe operation in industrial steam systems. This valve is primarily used for discharging sediments accumulated at the bottom of boilers. It operates with different control mechanisms depending on system pressure. Thanks to its pneumatic and manual control options, it offers flexibility to operators. In addition, it reduces maintenance costs and increases system efficiency. With these features, it supports both energy savings and workplace safety.

Areas of Use in Industrial Systems

This specialized valve is used in various industrial systems, primarily steam boilers. It is frequently preferred in the chemical, energy, and textile industries because it is designed to withstand high temperature and pressure. For example, Unox’s solutions in this field provide effective cleaning in factories. You can access detailed information via unox.

Control via Pneumatic Mechanism

The pneumatic system operates with compressed air and does not require operator intervention. Thanks to this feature, it does not require continuous monitoring while enabling system automation. This reduces workload and saves time. In addition, pneumatic valves respond quickly in emergency situations. For more technical details, you can browse the Unox Online product category.

Flexible Use with Manual Control

Some facilities prefer manual control because it allows operators to intervene instantly. Manual control systems are commonly used in small-scale plants. In addition, investment costs are low; however, regular maintenance is required. You can receive support for this product via Unox’s contact page: unox contact.

Durable Materials and Long Service Life

The Pneumatic and Manual Bottom Blowdown Valve – 33602 is manufactured from high-quality stainless steel. This provides the product with a long service life and delays wear. In addition, it reduces the risk of corrosion within the system; however, regular cleaning is required. You can access the product’s technical specifications via the Unox Online contact page.

Contributes to Energy Efficiency

With this valve, energy loss in the boiler is minimized because the blowdown operation is carried out only when needed. As a result, both water savings are achieved and fuel consumption is reduced. In addition, the overall efficiency of the system increases; however, the valve settings must be adjusted correctly. For energy-efficient solutions, you can visit the Unox page.

Ease of Installation and Maintenance

This product can be easily integrated into both horizontal and vertical piping systems. Installation time is short; however, professional support is recommended. In addition, during maintenance, the components can be easily disassembled and cleaned. In the long term, it helps reduce operating costs. For technical service, you can use the Unox Online contact link.